Inspiration

This project was inspired by a concept of automated matter which has taken form in many sci-fi films (X-Men, Watchmen, Matrix), and recently at the Media Lab. The idea is a hidden bridge that appears or materializes only when needed, enabling the user to confidently drive off a cliff or into the water, to be met by rising supports just in time. Ultimately the bridge supports shoudl support a car when present, and otherwise go away / retract / disentigrate.

X-Men – Magneto Escape

Light Bridge from Halo

Secret Garage Platform

InForm – Actuated Tabletop

Preliminary Sketches

Inputs

Light – Photoresistor

Photoresistors are light-dependent resistor (LDR), also referred to as a “photocell”. Resistance across them decreases with exposure to light. Wired from an analog read pin to ground.Read from an analog read pin.

Pros

+ Easy to detect – The kind of light detected is the same wavelength we perceive naturally. Being able to easily see the input signal makes debugging significantly easier.

+ No additional hardware – In most demonstration conditions, light – in the form of daylight, synthetic fluorescents, LED, and halogens – is present

Cons

+ Inconsistent – Visible light levels vary A LOT between spaces. This makes for a bad output for a linear actuator.

+ Reacts to ambient light – In the context of a full-scale implementation, a photocell input would result in the bridge delaying for clouds, or any other opaque object that could move over the bridge path.

+ Reaction not limited to the car – Part of the appeal of a bridge that materializes out of nowhere is the fact that it only works under certain conditions, or for certain people.

Magnetic Field – Hall Effect

Magnetic Field – Hall Effect

Hall effect vary the voltage drop from a power source according to the surrounding magnetic field- including the Earth’s resting magnetic force. THis allows it to sense up, down, and the presence of other electro-magnetic fields.

Pros

+ Reaction is limited to the presence of a magnet

+ Magnetic field detection would serve as a basic identifying factor that would enable only individuals cognizant of the requirements of the bridge to activate it, and do so discreetly

Cons

+ Magnets + electronics = ?x??1?$?

Other unknown side effects

Video Demo (clickthrough)

Output

Pneumatic Actuation

Air powered movements. Using one air compressors, gates are turned on and off to inrease/decrease pressure in tubes and chambers to create movement.

Pros

+ Air is pretty friendly

+ Compatible with water

+ System could scale relatively well

Cons

+ Requires a large air compressor

+ Requires weights for submersion

+ Air compressor makes noise

+ Actuation makes loud pops with each pressure release

+ Lots of hosing requires

+ No small form factors for cool models

+ $$$

Hydrolic Actuation

Basically the same as pneumatic, but using liquids instead of air.

Pros

+ Pressure isn’t an issue.

+ Scales well

+ Very compatible with submersion

Cons

+ Requires bulky/large reinforced/structural material

+ $$$$

Magnetic Actuation

Magnetic field detection would serve as a basic identifying factor that would enable only individuals cognizant of the requirements of the bridge to activate it, and do so discreetly.

Pros

+ Reaction is limited to the presence of a magnet

+ Very little background noise

+ $

Cons

+ Magnets + electronics = ?x??1?$?

+ Side effects

Stepper Motor

FSMO815

Stepper Motor / Lead Screw Actuation

Oringally I didn’t find stepper motors appealing, but then I discovered these steppers with lead screws that act as linear actuators. These are used for many 3-axis machines and other various uses. They are also used in CD/DVD drives to move both the CD chassis, and the laser scanner. Because CD/DVD drives are now essentially obsolete, China and Russia end up buying lots of them as e-waste, recycle them for parts, and then sell them for SUPER cheap. So these stepper motors are plentiful, and cheap.

Pros

+ 1.7″ actuation distance + Lots of torque

+ Tiny

+ Cheap. Between $1-2

Cons

+ No datasheet

+ Tricky to wire to

+ Does not come with a slider

Sourcing

+ Amazon

+ eBay

FSM0815-KD95 Specifications

+ Bipolar (2-phase) stepper motor

+ DC 5V

+ 1000RPM = 16.7 revs/s = 3.35cm/s actuation speed

+ 22 degree step angle

+ 16 pulse (pulses required to make one ful revolution)

+ Dimensions: 6×7.5×13.5mm / 0.24″ x 0.29″ x 0.53″ (L*W*H)

+ Screw Diameter : 2.5mm / 0.1″ Download My Model

+ Screw Length : 43mm / 1.7″

+ Weight: 33g

Stepper Sliders

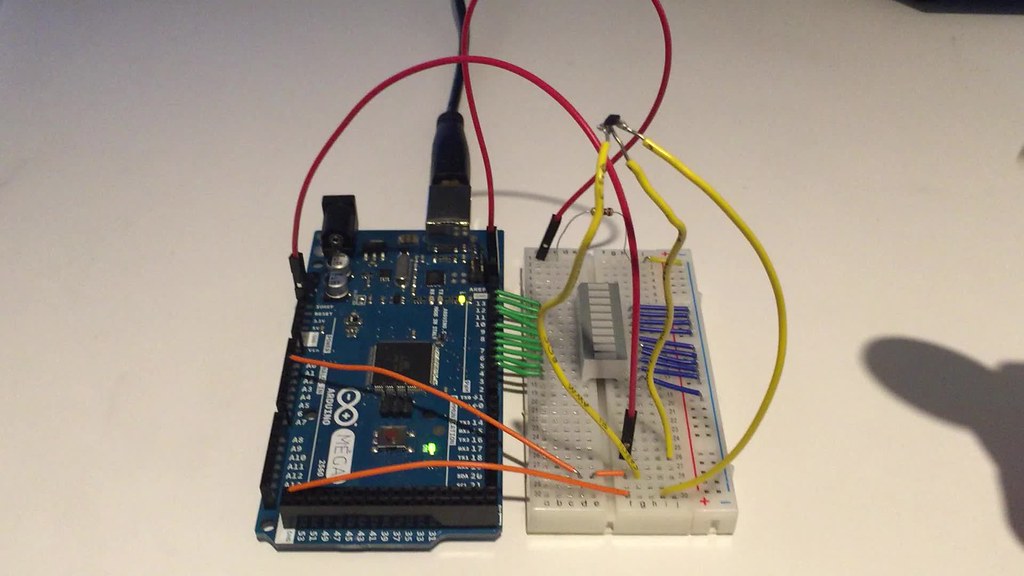

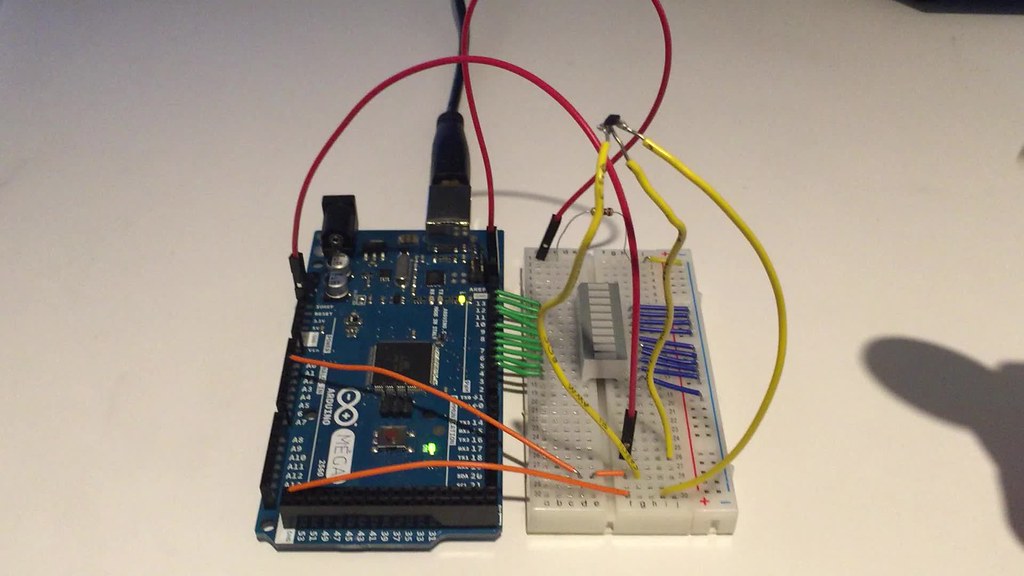

Electrical Design

I decided to make the array out of discreet baords with no communication, mostly for the sake of keeping things simple. Eventually I would like to make a version with centralized controlled, as this would allow me to create more wholistic movments and animations with the pylons.

My board design was based off of the hello.world.steppermotor example found on this page. I added a jumper to the board for a remote sensor daughter board, and moved te power jumper around to accomodate a series of baord being powered in series by one cable.

Autorouting in Eagle never gets old. Eventually I settled on this configuration.

Circuits (Bulk Print)

Exterior Cuts (Bulk Print)

I also designed chips for a power jack, and the remote sensor for each primary board.

Power Jack

Power Jack Circuits

Exterior Cut

Sensor Board

Sensor Circuits

Exterior Cut

Pylons

Final

Magnetic Field – Hall Effect

Magnetic Field – Hall Effect